.jpg)

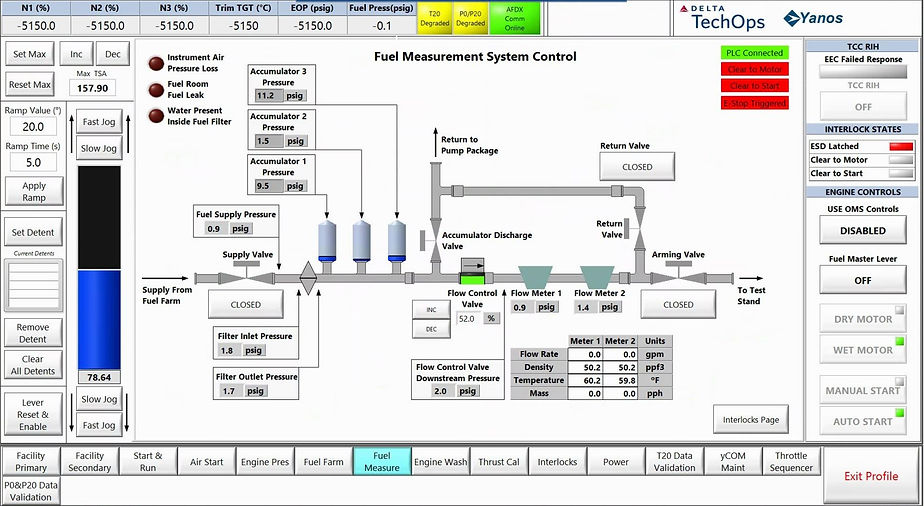

Visual Style Facility Monitoring and Control

Intuitive, Easily Configurable and Expandable Screens.

-

Using the same design philosophy as RealTime, the yCOM system provides easily configurable screens that provide a visual representation of the facility for feedback and control.

-

Powered by the yDEX Engine, the system is easily expandable to account for future facility hardware additions and changes.

-

The yCOM system automates your interlocks in a visual manner to ensure a safe and reliable engine start-up.

-

Thanks to the versatility in the Yanos software architecture (powered by LabVIEW), the yCOM system is easily expandable to account for any future engine models/variants additions.

Yanos Technologies Command Interface (yCOM)

The Future in Automation.

Yanos Technologies is committed to on-going Research & Development activities to ensure that our existing products are state-of-the-art. This is why we are proud to introduce the yCOM automation system, which brings the highest level of automation and safety for any control system application.

-

The yCOM is the centralized interface for the Yanos Technologies RealTime Control System (RCS).

-

Designed with Operators in mind, the yCOM system provides the highest level of automation while providing complete control and safety.

-

Capable of running through all required test procedures in semi or fully automatic mode.

-

Allows never before seen levels of data precision over multiple runs.

Automated Actions

Run Through Your Tests Automatically.

-

yCOM's fully automatic mode allows the system to run with any set of automated actions, without any interaction from the operator.

-

These fully automated sequences are designed to accomplish a complete functional test as defined by the engine test procedures, including the control of additional system settings and automated data capture.

-

yCOM's semi automatic mode breaks each test into steps that the operator can choose to execute sequentially.

-

yCOM's manual mode includes a number of additional features designed to aid the operator and increase data precision when perming multiple runs, these include:

-

Precise ramp actuation, moves the stepping automatically from position A to position B in the amount of time specified by the operator with incredible accuracy.

-

Programmable digital detents, these help the operators track and lock in place the throttle at key positions during the run.

-

Fast and Slow jogs, used for small lever adjustments.

-

Setting max throttle position, limits thrust output to a specified maximum.

-